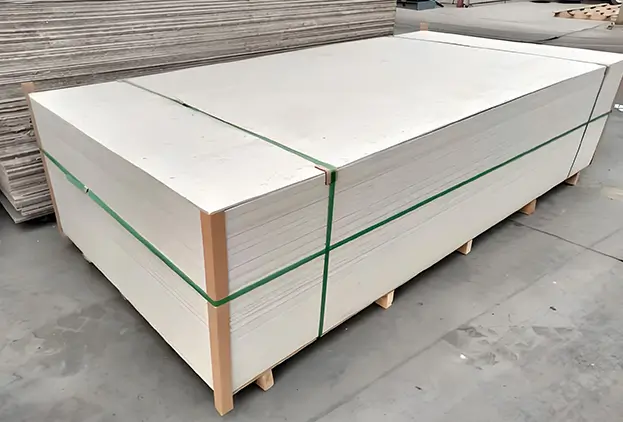

Calcium Silicate Insulation Board is a high-performance thermal insulation material with excellent heat resistance, low thermal conductivity, and outstanding mechanical strength, ideal for high-temperature industrial applications.

Chat on WhatsApp:

+8615038278221Email Us:

info@rsrefractories.com

Calcium Silicate Insulation Board is a rigid, lightweight insulation material manufactured from high-purity calcium compounds and silica, reinforced through advanced autoclaving processes. It offers excellent thermal insulation performance at elevated temperatures, combined with low density, high compressive strength, and superior dimensional stability.

This material is non-combustible, asbestos-free, and environmentally friendly, making it a safe and reliable solution for industrial insulation systems. Calcium Silicate Insulation Board also features good machinability, allowing easy cutting, shaping, and installation on-site. Its resistance to thermal shock and long service life help reduce energy consumption and maintenance costs in demanding operating environments.

| Item | Specification | ||||

| GSG-1 | GSG-2 | GSG-3 | GSG-4 | ||

| SiO2 % | 47~48 | ||||

| CaO % | 44~45 | ||||

| Mass Lost % | 6~7 | ||||

| Bulk Density kg/m3 | 230±10% | 250±10% | 270±10% | 300±10% | |

| CMOR MPa | ≥0.45 | ≥0.50 | ≥0.55 | ≥0.6 | |

| CCS MPa | ≥0.8 | ≥0.9 | ≥1.0 | ≥1.1 | |

| Thermal Conductivity W/(m·K) | 200℃ | ≤0.085 | ≤0.095 | ≤0.098 | ≤0.102 |

| 400℃ | ≤0.100 | ≤0.108 | ≤0.110 | ≤0.116 | |

| 600℃ | ≤0.152 | ≤0.156 | ≤0.158 | ≤0.164 | |

| 800℃ | ≤0.214 | ≤0.216 | ≤0.218 | ≤0.226 | |

| Use of Maximum Temperature ℃ | 1100 | ||||

| Linear Shrinkage % 1050℃×12h | ≤2 | ||||

Calcium Silicate Insulation Board is widely used in high-temperature insulation and energy-saving systems, including:

Industrial furnaces and kilns

Power plants and boiler insulation

Petrochemical and chemical processing equipment

Pipework, ducts, and vessel insulation

Steel, non-ferrous metal, and cement industries

Its excellent thermal efficiency and structural reliability make it an ideal choice for applications requiring long-term performance under extreme heat conditions.

Comprehensive Refractory Product Range

We manufacture 3 main types of refractory materials — refractory castables, high alumina cement, and refractory bricks — covering 100+ industrial furnace types worldwide.

Certified Quality and International Standards Compliance

All batches undergo strict quality control. Products comply with ISO, ASTM, and GB standards, ensuring reliable performance in high-temperature industrial applications.

Annual Production Capacity of 130,000 Tons

With a large-scale capacity of 130,000 tons per year, we guarantee stable supply and on-time delivery for long-term and large-volume projects.

Exported to 120+ Countries and 1,000+ Projects

Our products have been successfully delivered to over 120 countries, supporting more than 1,000 industrial projects, including cement, steel, incineration, glass, and petrochemical furnaces.

20+ Years of Experience in Refractory Manufacturing

With over 20 years of experience, we understand real furnace conditions and deliver materials proven in long-term industrial operations worldwide.

Professional Technical Support and Free Samples

We provide technical assistance from material selection to installation guidance, with free samples available for testing and supporting 1,000+ projects globally.

Fill out the form to request a free, detailed quote.