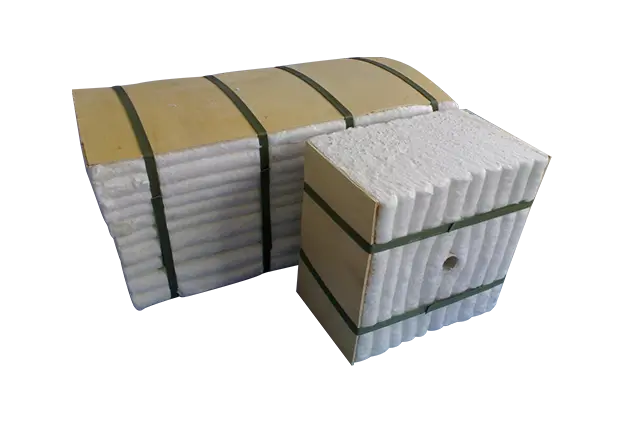

Ceramic Fiber Modules are lightweight, high-temperature insulation components made from ceramic fibers. They offer excellent thermal resistance, low thermal conductivity, and superior mechanical strength, making them ideal for efficient heat retention and energy saving.

Chat on WhatsApp:

+8615038278221Email Us:

info@rsrefractories.com

Ceramic Fiber Module is a kind of new type refractory kiln lining products for simplifying and quickening the kiln construction and improving kiln integrality. Ceramic Fiber Module has features of white color and regular sizes that can be fixed on the refractory anchor nails of kiln shell steel plate in the industrial kiln. Ceramic Fiber Modules have good thermal insulation effect that can improve the integrality of kiln insulation, which can be used as refractory insulation materials in ceramic industry and steel industry.

| Item Model | Ceramic Fiber Module | |||

| 1260 Saber block | 1400 Saber block | 1260 Uniblock | 1400 Uniblock | |

| Classification temperature (°C) | 1260 | 1400 | 1260 | 1400 |

| Density ( Kg/m3) | 160 , 192 , 210 | |||

| Linear shrinkage (%) | (1100℃x 24 hrs)1.0 | (1200 ℃x 24 hrs) 1.0 | ( 1100 ℃ x 24 hrs ) 1.0 | (1200℃ x 24 hrs) 1.0 |

| Thermal conductivity Kcal/mh °C (W/mK) ,ASTM C201 (160 kg/m3) | ||||

| Mean 400 °C | 0.09 | 0.09 | ||

| Mean 600 °C | 0.14 | 0.14 | 0.14 | 0.14 |

| Mean 800 °C | 0.21 | 0.21 | 0.2 | 0.2 |

| Mean1000 °C | 0.26 | 0.28 | ||

| Available size( mm/pc ) | 300*300*150 , 200 , 250 , 300 | |||

Petroleum industry furnace lining insulation; metallurgy industry furnace lining insulation; ceramics, glass and other building materials industry furnace lining insulation; heat treatment industry heat treatment furnace lining insulation; other industrial furnace lining

Comprehensive Refractory Product Range

We manufacture 3 main types of refractory materials — refractory castables, high alumina cement, and refractory bricks — covering 100+ industrial furnace types worldwide.

Certified Quality and International Standards Compliance

All batches undergo strict quality control. Products comply with ISO, ASTM, and GB standards, ensuring reliable performance in high-temperature industrial applications.

Annual Production Capacity of 130,000 Tons

With a large-scale capacity of 130,000 tons per year, we guarantee stable supply and on-time delivery for long-term and large-volume projects.

Exported to 120+ Countries and 1,000+ Projects

Our products have been successfully delivered to over 120 countries, supporting more than 1,000 industrial projects, including cement, steel, incineration, glass, and petrochemical furnaces.

20+ Years of Experience in Refractory Manufacturing

With over 20 years of experience, we understand real furnace conditions and deliver materials proven in long-term industrial operations worldwide.

Professional Technical Support and Free Samples

We provide technical assistance from material selection to installation guidance, with free samples available for testing and supporting 1,000+ projects globally.

Fill out the form to request a free, detailed quote.